| Radial spherical plain bearings | ||||||||

| Brand: | SKF GEH 110 ES-2LS bearing | ||||||||

| Our Price: | Ask for quotation | ||||||||

| Filling slots:Without | Model Number:GEH 110 ES-2LS | ||||||||

| Size: | 110mm x 180mm x 100mm | ||||||||

| Sliding contact surface combination: | Steel/PTFE/ sintered /bronze | ||||||||

| Material, inner ring: | Bearing steel | ||||||||

| Material, outer ring: | Steel | ||||||||

| Maintenance: | Maintenance-free | ||||||||

| Sealing: | Without /2RS | ||||||||

| Relubrication feature: | Without | ||||||||

| Radial spherical plain bearings | |||||||||

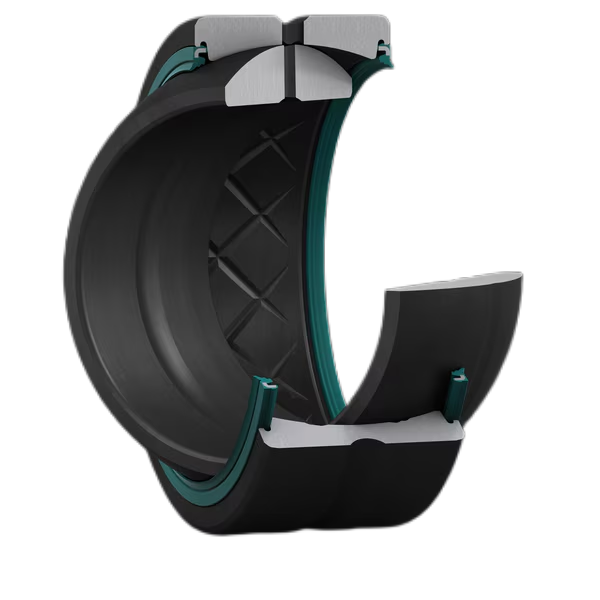

GEH 110 ES-2LS bearing Radial spherical plain bearing, maintenance-free, metric sizes These spherical plain bearings have a steel/PTFE sintered bronze contact surface combination and are maintenance-free. The sliding surfaces have to be externally protected from contaminants. These bearings are also available with a wider inner ring and a larger outside diameter (suffix GEH), which enable higher load ratings and larger tilt angles Designed for radial and combined radial and axial loads Long service life and maintenance-free Suitable for heavy, constant direction loads Low coefficient of friction High operating temperatures High sliding velocities and small operating clearances |  | ||||||||

| GEH 110 ES-2LS bearing Radial spherical plain bearing, requiring maintenance, metric sizes Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes a steel/steel sliding contact surface combination. The bearings require maintenance and can be relubricated only from the side. Designed for radial and combined radial and axial loads Suitable for heavy static, alternating or impact loads | ||||||||

| | |||||||||

GEH 110 ES-2LS bearing Radial spherical plain bearing, requiring maintenance, metric sizes Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes a steel/steel sliding contact surface combination. The bearings require maintenance and can be relubricated via lubrication holes and an annular groove in both rings. Designed for radial and combined radial and axial loads Suitable for heavy static, alternating or impact loads |  | ||||||||

| | |||||||||

| GEH 110 ES-2LS bearing Radial spherical plain bearing, maintenance-free, metric sizes Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes a steel/PTFE fabric sliding contact surface combination and the bearings are maintenance-free. Except for those with designation suffix TXGR, they have a double-lip contact seal (-2RS) or a triple-lip, heavy duty contact seal (-2LS) on both sides. Those with designation suffixes TXGR, TXG3E or TXG3A are made of stainless steel. Designed for radial and combined radial and axial loads Long service life and maintenance-free Suitable for very heavy, constant direction loads Low coefficient of friction | ||||||||

| | |||||||||

GEH 110 ES-2LS bearing Radial spherical plain bearing, requiring maintenance, sealed, metric sizes Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes a steel/steel sliding contact surface combination, a multi-groove lubrication system on the outer ring raceway and a triple-lip, heavy-duty contact seal on both sides. The bearings require maintenance and can be relubricated via lubrication holes and an annular groove in both rings. Designed for radial and combined radial and axial loads Long service life Minimal maintenance Multi-groove system extends service life at smaller oscillating movements Suitable for heavy static, alternating or impact loads |  | ||||||||

| | |||||||||

| SKF Explorer radial spherical plain bearing, virtually maintenance-free, sealed, metric sizes Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes an SKF Explorer steel/steel sliding contact surface combination. They are initially lubricated and have a triple-lip, heavy-duty contact seal on both sides. Compared to conventional steel/steel bearings, they have increased dynamic load ratings. Designed for radial and combined radial and axial loads Long service life Virtually maintenance-free Suitable for heavy static or impact loads | ||||||||

| | |||||||||

GEH 110 ES-2LS Radial spherical plain bearing, maintenance-free, metric sizes Radial spherical plain bearings are designed to accommodate radial and combined radial and axial loads, and also misalignment. This specific design includes a steel/PTFE fabric sliding contact surface combination and the bearings are maintenance-free. Except for those with designation suffix TXGR, they have a double-lip contact seal (-2RS) or a triple-lip, heavy duty contact seal (-2LS) on both sides. Those with designation suffixes TXGR, TXG3E or TXG3A are made of stainless steel. Designed for radial and combined radial and axial loads Long service life and maintenance-free Suitable for very heavy, constant direction loads Low coefficient of friction |  | ||||||||

Spherical Sliding Bearings: | |||||||||

GEH 110 ES-2LS bearing Spherical plain bearing Joint bearing is a type of spherical sliding bearing, with a sliding contact surface consisting of an inner spherical surface and an outer spherical surface. It can rotate and swing at any angle during motion. It is made using various special processing methods such as surface phosphating, blasting, gasket insertion, and spraying. Joint bearings have the characteristics of high load capacity, impact resistance, corrosion resistance, wear resistance, self centering, and good lubrication. Basic information The structure of joint bearings is simpler than that of rolling bearings, mainly consisting of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface. Joint bearings are generally used for low-speed swinging motion (i.e. angular motion). Due to the spherical sliding surface, they can also perform tilting motion (i.e. centering motion) within a certain angle range. They can still work normally when the supporting shaft and the shaft shell hole are not concentric enough. characteristic Joint bearings can withstand large loads. According to its different types and structures, it can withstand radial loads, axial loads, or combined loads that exist both radially and axially. Due to the composite material embedded on the outer spherical surface of the inner ring, this bearing can generate self-lubricating during operation. It is generally used for low-speed swing motion, low-speed rotation, and can also perform tilting motion within a certain angle range. When the support shaft and the shaft shell hole are not concentric, it can still work normally. Self lubricating joint bearings are applied in industries such as water conservancy and professional machinery. application Joint bearings are widely used in engineering hydraulic cylinders, forging machines, construction machinery, automation equipment, automotive shock absorbers, water conservancy machinery and other industries. Joint bearings are spherical sliding bearings, which are basically composed of inner and outer rings with spherical sliding spherical contact surfaces. Depending on its structure and type, it can withstand radial loads, axial loads, or combined loads acting both radially and axially. Due to the large spherical sliding contact area and inclination angle of joint bearings, as well as the special process treatment methods adopted by most joint bearings, such as surface phosphating, galvanizing, chrome plating or external sliding surface lining, gasket insertion, spraying, etc., it has a large load capacity and impact resistance, and has the characteristics of corrosion resistance, wear resistance, self centering, good lubrication or self-lubricating without lubricating dirt pollution. Even if installed incorrectly, it can work normally. Therefore, joint bearings are widely used for lower speed swing, tilt, and rotation movements. The function of joint bearings Due to the completely different structural form and working mechanism from rolling bearings, joint bearings have their own technical characteristics and maintenance requirements. working temperature The allowable working temperature of joint bearings is mainly determined by the matching materials between the sliding surfaces of the bearings, especially the plastic sliding surfaces of self-lubricating joint bearings, whose load-bearing capacity tends to decrease at high temperatures. When the sliding surface material of a lubricated joint bearing is paired with steel, its allowable working temperature depends on the allowable working temperature of the lubricant. But for all lubrication and self-lubricating joint bearings, they can be used within the temperature range of -30 ℃ to+80 ℃ and maintain the correct bearing capacity. obliquity The inclination angle of a joint bearing is much larger than that of a general adjustable center rolling bearing, making it suitable for use in supporting parts with low concentricity requirements. The inclination angle of a joint bearing varies with the size, type, sealing device, and support form of the bearing structure. The inclination angle range of a general radial joint bearing is 3 ° to 15 °, the inclination angle range of an angular contact joint bearing is 2 ° to 3 °, and the inclination angle range of a thrust joint bearing is 6 ° to 9 °. cooperate In any case, the selected fit of the joint bearing shall not cause uneven deformation of the ring. The selection of its fit properties and grades must be determined based on the working conditions of the bearing type, support form, and load size. Loading and unloading The loading and unloading of joint bearings should follow the following principles, that is, the force applied during assembly and disassembly cannot be directly transmitted through the spherical sliding surface. In addition, auxiliary loading and unloading tools such as sleeves and dismantling tools should be used to directly and uniformly apply the external loading and unloading force to the matched ring, or to use auxiliary methods such as heating for unloaded loading and unloading. install When assembling the joint bearing series, it is necessary to pay special attention to the position of the outer ring dividing surface. To avoid direct load on the dividing surface, it is necessary to maintain the dividing surface at a right angle to the corresponding direction. lubrication When the speed generated by applying load and swinging motion is small, the oil fed joint bearing can be operated without lubrication. However, in general, it is necessary to regularly replenish oil and fat. It is recommended to shorten the lubrication cycle moderately during the initial installation and operation. Oil free joint bearings can be used without lubrication. However, if lithium soap based grease is added before operation, the service life of the joint bearing can be further extended. If grease is injected into the space around the bearing, the joint bearing will be more effective in preventing the invasion of dust and foreign objects. Joint bearing type Plain radial bearing (1) GE... E-type: single seam outer ring, without lubricating oil groove. Capable of withstanding radial loads and smaller axial loads in any direction. (2) GE... ES type: single seam outer ring with lubricating oil groove. Capable of withstanding radial loads and smaller axial loads in any direction. (3) GE... ES-2RS type, GEEW... ES-2RS type: single seam outer ring, with lubricating oil groove, with sealing rings on both sides. Capable of withstanding radial loads and smaller axial loads in any direction. (4) GE... ESN type: single seam outer ring, GE... XSN type: double seam outer ring (split outer ring), with lubricating oil groove, and outer ring with stop groove. Capable of withstanding radial loads and smaller axial loads in any direction. But when the axial load is borne by the stop ring, its ability to withstand the axial load decreases. (5) GE... HS type: The inner ring has a lubricating oil groove, and the double half outer ring can adjust the clearance after wear. Capable of withstanding radial loads and smaller axial loads in any direction. (6) GE... DE1 type: The inner ring is made of quenched bearing steel, and the outer ring is made of bearing steel. During the assembly of the inner ring, it is extruded into shape and has lubricating oil grooves and holes. Bearings with an inner diameter less than 15mm, without lubricating oil grooves and holes. Capable of withstanding radial loads and smaller axial loads in any direction. (7) GE... DEM1 type: The inner ring is made of hardened bearing steel, and the outer ring is made of bearing steel. During the assembly of the inner ring, it is extruded into shape. After the bearing is installed in the bearing seat, the end groove is pressed out on the outer ring to fix the bearing axially. Capable of withstanding radial loads and smaller axial loads in any direction. (8) GE... DS type: The outer ring has assembly grooves and lubrication grooves. Limited to large-sized bearings only. Capable of withstanding radial loads and smaller axial loads in any direction (one side of the assembly groove cannot withstand axial loads). Angular contact joint bearing The GAC... S-shaped inner and outer rings are made of quenched bearing steel, and the outer ring has oil grooves and holes. Capable of withstanding radial loads and axial (combined) loads in one direction. Thrust joint bearing The GX... S-shaped shaft ring and seat ring are both made of hardened bearing steel; The seat ring has oil grooves and holes. Capable of withstanding axial or combined loads in one direction (at which point the radial load value shall not exceed 0.5 times the axial load value). Rod end joint bearing (1) SI... E type is the assembly of GE... E type bearings and rod ends. The rod end is equipped with internal threads and made of carbon structural steel, without lubricating oil grooves. Capable of withstanding radial loads and axial loads less than or equal to 0.2 times radial loads in any direction. (2) SA... E type is the assembly of GE... E type bearings and rod ends. Rod end with external thread, made of carbon structural steel; No lubricating oil groove, capable of withstanding radial loads and axial loads less than or equal to 0.2 times radial loads in any direction. (3) SI... ES type is the assembly of GE... ES type bearings and rod ends. Rod end with internal thread, made of carbon structural steel; There is a lubricating oil tank. Capable of withstanding radial loads and axial loads less than or equal to 0.2 times radial loads in any direction. (4) SA... ES type is the assembly of GE... ES type bearings and rod ends. Rod end with external thread, made of carbon structural steel; There is a lubricating oil tank. Capable of withstanding radial loads and axial loads less than or equal to 0.2 times radial loads in any direction. (5) SIB... S-shaped rod end with internal thread, made of carbon structural steel; The inner ring is made of hardened bearing steel; There is a lubricating oil tank. Capable of withstanding radial loads and axial loads less than or equal to 0.2 times radial loads in any direction. (6) SAB... S-shaped rod end with external thread, made of carbon structural steel; The inner ring is made of hardened bearing steel; There is a lubricating oil tank. Capable of withstanding radial loads and axial loads less than or equal to 0.2 times radial loads in any direction. (7) The SQ... type is a ball joint bearing with a rod end made of carbon structural steel; The ball head is made of carburized steel. Capable of withstanding radial loads and smaller axial loads in any direction. Self lubricating radial joint bearing (1) GE... C-type and GE... T-type: extruded outer ring, sliding surface of outer ring made of sintered bronze composite material; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Limited to small-sized bearings only. The outer ring is made of bearing steel, and the sliding surface is made of a layer of polytetrafluoroethylene fabric. The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding loads in the same direction, while also bearing radial loads, capable of withstanding smaller axial loads in any direction. (2) GE... CS-2Z type: The outer ring is made of bearing steel, and the sliding surface is made of sintered bronze composite material; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium; Equipped with dust covers on both sides. Capable of withstanding loads in the same direction, while also bearing radial loads, capable of withstanding smaller axial loads in any direction. (3) GEEW... T-type: The outer ring is made of bearing steel, and the sliding surface is made of a layer of polytetrafluoroethylene fabric; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding loads in the same direction, while also withstanding radial loads and smaller axial loads in any direction. (4) GE... F-type: The outer ring is made of quenched bearing steel, the sliding surface is made of glass fiber reinforced plastic with polytetrafluoroethylene as an additive, the inner ring is made of quenched bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding moderate radial loads with no change in direction. (5) GE... F2 type: The outer ring is made of glass fiber reinforced plastic, and the sliding surface is made of glass fiber reinforced plastic with polytetrafluoroethylene as an additive; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding moderate radial loads with no change in direction. (6) The GE... FSA type outer ring is made of medium carbon steel, and the sliding surface is composed of glass fiber reinforced plastic discs with polytetrafluoroethylene as an additive, which are fixed on the outer ring with a fixator; The inner ring is made of hardened bearing steel. Used for large and extra large bearings. Can withstand large radial loads. (7) GE... FIH type outer ring is made of quenched and hardened bearing steel; The inner ring is made of medium carbon steel, and the sliding surface is composed of glass fiber reinforced plastic discs with polytetrafluoroethylene as an additive, which are fixed on the inner ring with a fixator; Double half outer ring. Used for large and extra large bearings. Can withstand large radial loads. Self lubricating angular contact joint bearings GAC... The F-shaped outer ring is made of hardened bearing steel; The sliding surface is made of glass fiber reinforced plastic with polytetrafluoroethylene as an additive; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding radial loads and axial (combined) loads in one direction. Self lubricating thrust joint bearing The GX... F-shaped seat ring is made of quenched bearing steel, and the sliding surface is made of glass fiber reinforced plastic with polytetrafluoroethylene as an additive. The shaft ring is made of quenched bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding axial or combined loads in one direction (at which point the radial load value shall not exceed 0.5 times the axial load value). Self lubricating rod end joint bearing (1) SI... C type is the assembly of CE... C type bearings and rod ends. The rod end is threaded internally and made of carbon structural steel. Capable of withstanding loads in the same direction. Capable of withstanding axial loads less than or equal to 0.2 times the radial load in any direction while bearing radial loads. (2) SA... C type is the assembly of CE... C type bearings and rod ends. The rod end is threaded externally and made of carbon structural steel. Capable of withstanding loads in the same direction. Capable of withstanding axial loads less than or equal to 0.2 times the radial load in any direction while bearing radial loads. (3) SI... CS-2Z type is the assembly of GE... CS-2Z type bearings and rod ends. The rod end is threaded internally and made of carbon structural steel. Capable of withstanding axial loads less than or equal to 0.2 times the radial load in any direction while bearing radial loads. (4) SA... CS-2Z type is the assembly of GE... CS-2Z type bearings and rod ends. The rod end is threaded externally and made of carbon structural steel. Capable of withstanding loads in the same direction. Capable of withstanding axial loads less than or equal to 0.2 times the radial load in any direction while bearing radial loads. (5) SIB... C-shaped rod end with internal thread, made of carbon structural steel, and sliding surface made of sintered bronze composite material; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding radial loads with no change in direction. (6) SAB... C-shaped rod end with external thread, made of carbon structural steel, and sliding surface made of sintered bronze composite material; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding radial loads with no change in direction. (7) SIB... F-shaped rod end with internal thread, made of carbon structural steel, sliding surface made of glass fiber reinforced plastic with polytetrafluoroethylene as additive; The inner ring is made of hardened bearing steel, and the sliding surface is plated with hard chromium. Capable of withstanding radial loads with no change in direction. (8) SAB... F-shaped rod end with external thread, made of carbon structural steel, and sliding surface made of glass fiber reinforced plastic with polytetrafluoroethylene as an additive; The inner ring is made of hardened bearing steel with a sliding surface plated with hard chromium. Capable of withstanding radial loads with no change in direction. (9) The SQ... L-type is made of special self-lubricating alloy material and can withstand radial loads and smaller axial loads in any direction. | |||||||||

Questions about SKF - Sliding Bearings ?

For further details on this product please directly contact our sales department under shh@dmsw.com | |||||||||

Our products

| |||||||||

| Bearing By Types | Bearings for Hobby | Ceramic Ball Bearings | Flanged Ball Bearings | ||||||

| V Belts | Oil Seals | Anti-Friction Bearings | Washers/Snap Rings | Tools & Lubricants | |||||

| Thrust Bearing | Thin Section Bearings | Roller Bearing | Plain Bushings | One Way & Clutches | |||||

| IJK Made in Japan | Mounted Bearings | Metric Miniature Bearings | Metric Bearings | Loose Bearing Balls | |||||

| Linear Motion Systems | Lazy Susans Turntables | Inch (imperial) Sizes | High Temperature | ||||||

| THK | KOYO | FYH | NMB | ||||||

| SNR | INA | RBC | NACHI | ||||||