| Deep groove ball bearing | ||||||||

| Brand: | 6203 bearing | ||||||||

| Our Price: | $1.50 Ask for quotation | ||||||||

| Filling slots:Without | Model Number:6203 | ||||||||

| Size: | 17mm x 40mm x 12mm | ||||||||

| Number of rows: | 1 | ||||||||

| Locating feature, bearing outer ring: | None | ||||||||

| Bore type: | Cylindrical | ||||||||

| Cage: | Sheet metal | ||||||||

| Matched arrangement: | No | ||||||||

| Radial internal clearance: | CN C2 C3 C4 | ||||||||

| Tolerance class: | Class P6 (P5) | ||||||||

| Material, bearing: | Bearing steel | ||||||||

| Seals Type: | Open type ZZ 2Z 2RS1 DDU VV DW | ||||||||

| Lubricant | Grease | ||||||||

| Deep groove ball bearing with seals or shields | |||||||||

Deep groove ball bearing with seals or shields Single row deep groove ball bearings with seals or shields are particularly versatile, have low friction and are optimized for low noise and low vibration, which enables high rotational speeds. They accommodate radial and axial loads in both directions, are easy to mount, and require less maintenance than many other bearing types. The integral sealing can significantly prolong bearing service life because it keeps lubricant in the bearings and contaminants out.Integral sea ling prolongs bearing service life Simple, versatile and robust design Low friction and high-speed capability Accommodate radial and axial loads in both directions Require little maintenance |  | ||||||||

Knowledge and introduction of bearings : | |||||||||

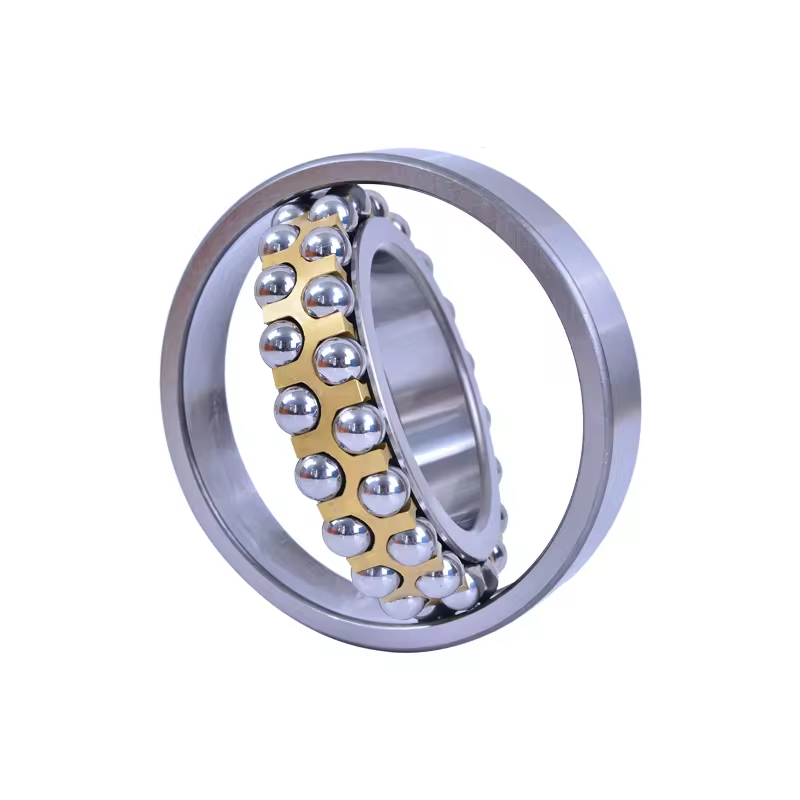

Self - aligning Ball Bearing: A Comprehensive Overview 1. Definition and Structure A self - aligning ball bearing is a type of rolling - element bearing. It consists of an inner ring, an outer ring, a set of balls, and a cage that holds the balls in position. The key feature of this bearing is its ability to self - align. The outer ring has a spherical raceway, which allows the bearing to compensate for misalignments between the shaft and the housing. 2. Operating Principle and Advantages 3. Applications | |||||||||

For further details on this product please directly contact our sales department under shh@dmsw.com | |||||||||

Our products

| |||||||||

Ball Bearings | Bearing By Types | Bearings for Hobby | Ceramic Ball Bearings | Flanged Ball Bearings | |||||

| V Belts | Oil Seals | Anti-Friction Bearings | Washers/Snap Rings | Tools & Lubricants | |||||

| Thrust Bearing | Thin Section Bearings | Roller Bearing | Plain Bushings | One Way & Clutches | |||||

| IJK Made in Japan | Mounted Bearings | Metric Miniature Bearings | Metric Bearings | Loose Bearing Balls | |||||

| Linear Motion Systems | Lazy Susans Turntables | Inch (imperial) Sizes | High Temperature | ||||||

SKF | NSK | FAG | TIMKEN | IKO | |||||

NTN | THK | KOYO | FYH | NMB | |||||

GMN | SNR | INA | RBC | NACHI | |||||